Premier Co-op

April Energy News

Remember last month when I was talking smack about winter being over? I wasn’t ready to accept it and when I heard a blizzard was raging in the upper peninsula of Michigan the fir...

As all farmers know, it takes a great deal of work (and some luck) to get a crop planted, grown, and brought back to the silage storage unit to be fed to our precious livestock. There are a variety of ways that we can add value to that plant before it gets harvested – but what about as we harvest and proceed to feed it out?

Proper silage making starts with great compaction and eliminating oxygen as quickly as possible. Whether that is having the correct pressure in a bagger, following ‘The rule of 800’ (packing tractor weight = 800 * tons of forage delivered/hour) in a bunker silo or silage pad, or filling up a silo in a timely manner and getting it covered, these are the first huge steps in the silage making process. Increasing DM packing density from 16 to 18 lbs. DM/cu. Ft. alone can increase storage capacity by 12.5%.

Using inoculant is encouraged, however, remember that not all are created equal. Use a science-based, research-proven inoculant. The goal of doing so is to drive the pH down within 3 days of ensiling, to reduce DM loss through fermentation and maximize aerobic stability at feed out.

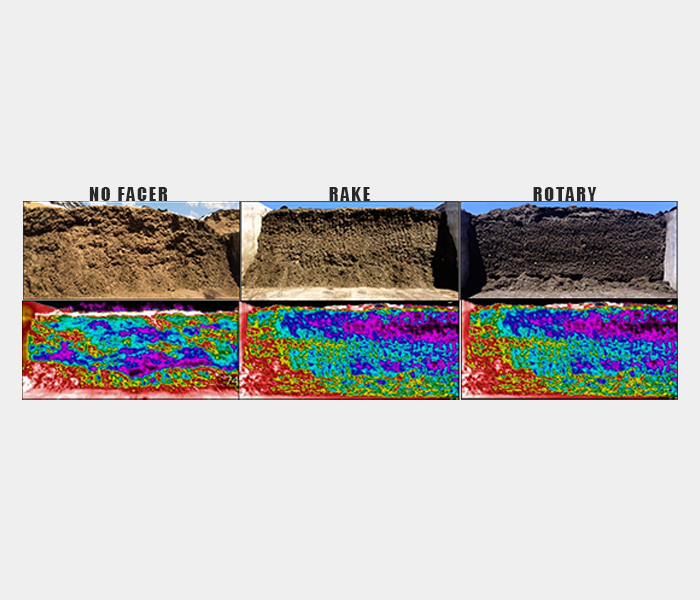

Forage management becomes a bit of a different beast in the upcoming months versus what is (almost) behind us. Keeping a clean face with minimal loose feed has HUGE impacts on what can grow in our silage storage units from day to day. Rake defacers are becoming increasingly popular in demand with fewer components to manage and do a considerably better job than no facer at all. Rotary facers remain the most elite at keeping a solid, compact surface. If we have applied a buchneri bacteria to our feedstuffs, we know they should have more stability. The use of dry and/or liquid acid products can make a great addition to the feed bunk on the hottest of summer days but can only do so much if the feed is heating long before it hits the mixer.

1st crop will be here before we know it. Our nutrition team can offer an array of services. For instance, FLIR cameras and temperature probes can be used to check out areas of feed that could be heating and losing value before it even reaches a cow’s mouth. Do not hesitate to reach out to a nutritionist on the Premier team for assistance in managing your forage.